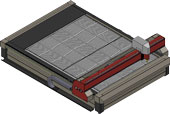

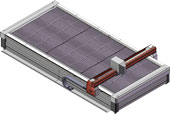

XM EVOLUTION cutting system

XM EVOLUTION is a complete high-definition large format plasma cutting system. A primary

feature of this system is the modularity of the length, which allows you to extend the machine, even

as an upgrade after purchase.

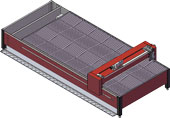

The cutting head, which includes the plasma torch and any other accessories described in the

appendix, runs along toughened and rectified guides, by means of a dual helical rack and pinion.

The torch moves in the vertical axis via a ball screw drive, on linear ball screw guides. During the

cutting phase this vertical movement also serves to compensate the undulation of the sheet using

feedback from the arc voltage; thereby keeping the torch at a constant distance from the sheet

during cutting; an extremely important factor for the life of the consumables and the cutting quality.

The torch unit is fitted with an anticollision system, which prevents the torch being broken and

shutting the machine down in the case of accidental impact. This system was created and built

entirely by FMT, thereby allowing total integration with numerical control.

The gantry, comprising a high-rigidity square section beam and two shoulders which carry the

motors and the electrical and system connections, scrolls on toughened guides on two racks driven

by motors connected within the gantry to ensure maximum acceleration and precision.

The electronic component of the movement comprises brushless servo motors with high resolution

encoders, controlled by entirely digital actuators integrated within the motors. These actuators are

connected to the CNC via a digital bus.

The sheet being worked is placed on a grille made up of simple rectangular strips of metal, which

can be very simply and rapidly replaced, for which a design plan is supplied.

The grille can rest on a vacuum workbench, is modular and divided into sections, to concentrate the

suction which is maintained below the cutting zone. Otherwise, it can be placed on the machine

chassis and the suction takes place via an vacuum hood which moves below the grille in harmony

with the gantry. This solution, which achieves a significant saving in investment and operating costs

(less power required for the vacuum unit) has the following limits:

- Maximum machine length 6000 mm.

- Maximum cutting current 130 A.

- Torch height: 100 mm

- Standard usable widths:

- 1500, 2000, 2500, 3000

- For custom requirements greater widths can also be supplied.

- Standard usable lengths:

- From 3000 up to 24000, as well as to order.